Interceptor oil removal is a new oil-water separation technology concept different from “adsorption oil removal”, based on a composite modified “HK” special materials developed by chemical methods, physical methods to form a spatial state (three-dimensional) interceptor module, when the spatial state of the interceptor membrane in the When the spatial blocking membrane is under the working condition of water saturation, it can automatically have the following special functional properties:

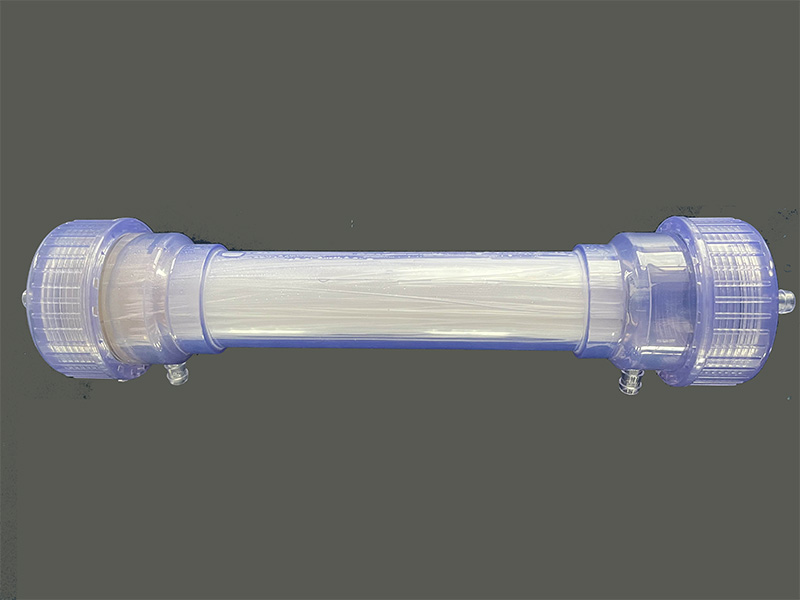

Our company independently developed the HK interception oil removal membrane series products: HKA, HKB, HKD, HKH, etc. applied in different fields.

1. It has extremely sensitive identification and differentiation ability for oil and water;

2. With the rebound function of rejecting the adhesion of oil;

3. When selectively applying unidirectional water pressure to the interception membrane, it can let the water particles be guided to displace and pass through, thus showing the special function of barrier effect of “water over oil but not”.

It is suitable for petroleum refining, condensate oil removal and iron removal, oil spill pollution emergency response, wastewater purification, sedimentary water automatic water cut, etc.

Advantageous features of the technology of “blocking oil removal”:

Relative to the traditional oil-water separation technology, intercepting oil removal technology has the following unique advantages:

1 “Interception of oil removal” technology advantages – “fine”.

Can make the oil-water separation accuracy of 0.1mg / L or less, which is unimaginable in the traditional process based on the principle of “adsorption”. When the oil content of incoming water is constantly changing and very high, the oil removal precision is very high and stable.

2 “Interceptor oil removal” technology advantage two – “safe”:

According to the technology in the oil refining enterprises for many years of operation practice shows that: the use of “blocking oil” theory of manufacturing oil removal equipment in the use of the cycle, in addition to the oil precision are stable within the design accuracy, with a high degree of safety and reliability, completely eliminated due to the condensate oil, to the boiler brought about by the security risks, so that the customer to do a high level of peace of mind. The customer can have a high degree of peace of mind.

3 “blocking oil” technology advantage three – “stable”:

The traditional process on the oil content of water requirements are high, generally no more than 10mg / L, intercepting technology in 300 ~ 500mg / L and 1000mg / L short-term large oil impact, can still achieve the rated oil removal accuracy. The oil removal accuracy of the traditional process fluctuates with the fluctuation of the oil content of the incoming water, and the oil removal accuracy of the interception theory basically does not change with the fluctuation of the oil content.

4 “Interception in addition to oil” technology advantage four – “things”:

Chemical process has been completed before the installation of equipment, the use of the process does not add any chemicals, a purely physical process. Interceptor materials in water saturation, the formation of HK materials for the process skeleton, water as the working medium of the dynamic selection of impermeable membrane, oil to oil recovery, water to water, so no need to backwash.

5 “blocking oil removal” technology advantage five – “since”:

When the device is subjected to accidental destructive oil contamination, once the accidental working condition is excluded and normal working condition is restored, the interception unit has the self-purifying self-cleaning ability of automatic self-purification recovery function.

6 “Intercepting and removing oil” technology advantage six – “hot”:

The HY “Interceptor Degreasing” device still has a very good oil-water separation effect under the condition of 90℃ water temperature. This can fully maintain the thermal energy of condensate. The use of adsorption of oil removal process must be reduced to the water temperature below 50 ℃, otherwise it will be due to the oil at higher temperatures in the infiltration of permeability increased significantly and easily penetrate the filter layer, the higher the temperature of the activated carbon adsorption capacity decreases accordingly.

7 “blocking oil removal” technology advantage seven – “tune”:

The application of traditional oil removal technology to produce the device can not be artificially designed for the precision of the device. And “blocking oil” technology can be completely according to customer requirements will be designed to 0.5mg / L or 0.3mg / L, or even higher precision.

8 “Interception of oil” technology advantage eight – “collection”:

The application of “intercepting oil removal” technology, can be oily wastewater for high-precision separation, so as to achieve the recovery of oil and water respectively, in the case of zero pollution, zero discharge, not only completely solve the problem of oil pollution, but also to achieve the recycling of energy. And the traditional oil removal technology is only the pollution adsorption transfer, can not achieve the effect of complete oil removal.

9 “Interception of oil” technology advantage nine – “simple”:

Application of “interception of oil removal” technology to prepare the device, the operation is very simple, without the need for a person on duty operation.

10 “Interception of oil removal” technology advantage ten – “low”:

“Interception in addition to oil” device in addition to the effective use of the material cycle does not produce any backwash, regeneration of water consumption, energy consumption, drug consumption, there will be no backwash wastewater discharges occurring in the sewage treatment costs, no need to specialize in the post also saved a considerable amount of labor wages. It is estimated that a processing capacity of 100 tons / hour of oil removal device, in addition to the recovery of a large amount of oil each year, but also to recover 840,000 tons of high-temperature condensate to 6 ~ 12 yuan / ton, the annual economic benefits can be created 5 ~ 10 million yuan, while the operating cost of the oil removal device is only 25 ~ 50 million yuan.